Micro-Via Advantages in Multilayer PCBs

Micro-vias are laser-drilled holes (typically 100–150μm diameter) that connect adjacent layers in HDI PCBs. Unlike mechanically drilled through-holes, micro-vias enable higher density routing and improved electrical performance. Here’s why designers choose micro-via technology.

Key Benefits

Shorter Signal Paths

Micro-vias connect only adjacent layers, eliminating the long vertical stubs created by through-hole vias. This results in:

- Shorter trace lengths – signals travel less distance

- Fewer signal layers needed – more efficient routing in less space

- Better signal integrity – reduced inductance and capacitance

Improved High-Frequency Performance

The shorter signal paths directly benefit RF and high-speed designs:

- Enhanced RF capability – less parasitic inductance

- Improved EMC characteristics – reduced radiation and coupling

- Cleaner impedance control – fewer discontinuities in transmission lines

Higher Component Density

Micro-vias unlock routing options that aren’t possible with through-holes:

- More room for components – via-in-pad allows placement directly under BGAs

- Single-sided assembly becomes viable – avoiding the cost of double-sided placement

- Smaller PCB footprint – same functionality in less board area

For maximum component density, consider the R7011 build which combines buried vias with micro-vias on both surfaces.

Better Reliability

Contrary to early concerns, micro-vias have proven more reliable than through-holes:

- Lower thermal stress – smaller copper volume expands less during reflow

- No barrel cracking – the failure mode that affects long through-holes

- Proven in automotive and aerospace – extensively tested per IPC standards

Additional Advantages

- Embedded passives possible – resistors can be integrated on layers 2 and n-1

- Fewer drilled holes – reduces drilling time and tool wear

- Environmentally friendly – less material waste than mechanical drilling

When to Use Micro-Vias

Micro-via HDI technology makes sense when:

- BGA pitch is 0.8mm or less and fanout requires via-in-pad

- Signal integrity requirements demand controlled impedance with minimal stubs

- Board size is constrained and through-hole routing won’t fit

- High-frequency operation (>1GHz) requires minimal parasitic effects

For simpler designs with larger BGAs (1.0mm+ pitch), standard multilayer builds with blind vias may be more cost-effective.

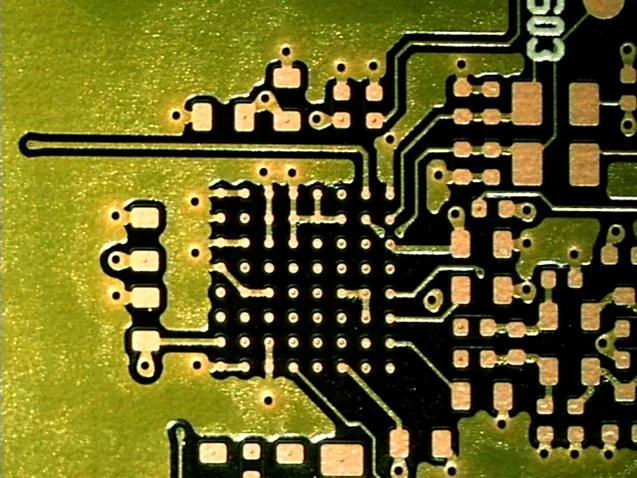

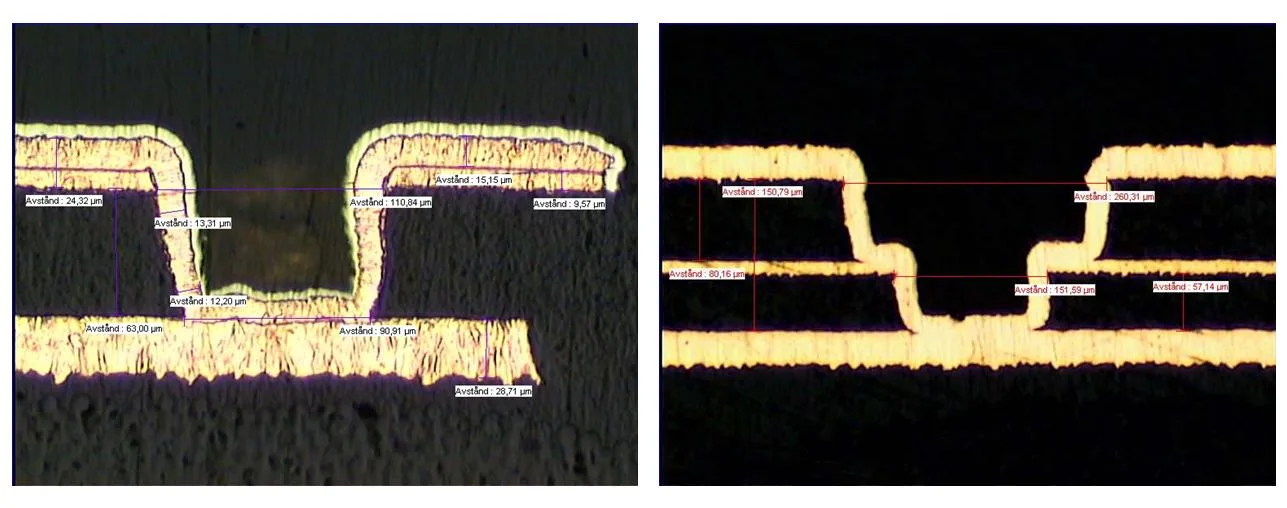

Micro-Via Examples

BGA fanout example: 64 contacts, 0.8mm pitch, 0.3mm pad, 0.15mm trace/space, 0.3mm vias, 0.1mm micro-vias

UV laser-drilled micro-via in RCC (resin-coated copper) foil: 0.1mm diameter, stepped 0.2mm to 0.1mm

Learn More

- PCB Build Illustrations – see micro-via stackups R7009–R7020

- Multilayer PCB Stackups – compare HDI vs. standard constructions

- Reliability Testing for Microvias in Printed Wire Boards (PDF) – EIPC conference paper on micro-via reliability

Need help with an HDI design? Our engineers can review your stackup and recommend the most practical micro-via configuration. Get in touch.