The Problem: Choosing the Right Laminate

Every PCB design starts with a materials decision that affects cost, performance, and reliability. Choose standard FR-4 for an RF application and you’ll fight signal loss. Specify exotic materials for a simple digital board and you’ll waste budget. The challenge is matching material properties - dielectric constant, loss tangent, thermal stability - to your actual requirements.

This guide provides the specifications you need to make informed laminate decisions, organised by application with links to manufacturer data sheets.

Key Material Properties

Understanding these properties helps you select the right laminate:

- Dk (Dielectric Constant) - Determines impedance and signal velocity. Lower Dk = faster signals, easier impedance control

- Df (Dissipation Factor) - Signal loss per unit length. Critical above 1 GHz; lower is better

- CTE (Coefficient of Thermal Expansion) - Dimensional change with temperature. Z-axis CTE affects via reliability

- Tg (Glass Transition Temperature) - Temperature where the laminate softens. Must exceed reflow temperatures for lead-free assembly

- Td (Decomposition Temperature) - Where the material begins to break down chemically

Material Selection by Data Rate

| Data Rate | Target Df @ 10 GHz | Material Class | Examples |

|---|---|---|---|

| ≤25 Gbps | ~0.010 | Mid-loss FR-4 | Isola 370HR, standard high-Tg |

| 56 Gbps PAM4 | 0.004-0.005 | Low-loss | Megtron 6, I-Tera MT40 |

| 112 Gbps PAM4 | ≤0.002 | Ultra-low-loss | Megtron 7/8, Tachyon 100G, IT-988GSE |

| 224 Gbps PAM4 | ≤0.0015 | Extreme-low-loss | Megtron 8, TerraGreen 400G |

Standard FR-4 Materials

| Material | Dk @ 10 GHz | Df @ 10 GHz | Tg °C | Td °C | CTE Z (pre-Tg) | Data Sheet |

|---|---|---|---|---|---|---|

| Standard FR-4 Tg 135 | 4.3-4.5 | 0.018-0.020 | 140 | 305-315 | 55-70 ppm/°C | S1141 FR-4 |

| FR-4 Tg 150 | 4.2-4.4 | 0.015-0.018 | 155 | 330-348 | 50-65 ppm/°C | S1000/S1000B |

| Isola FR406 Tg 170 | 3.92 | 0.0172 | 170 | 300 | 60 ppm/°C | S1000-2 & Prepreg |

| Isola 370HR Tg 180 | 3.92 | 0.0250 | 180 | 340 | 45 ppm/°C | Isola Product Guide (PDF) |

| Isola FR408 | 3.65 | 0.0125 | 180 | 360 | 60 ppm/°C | Isola Product Guide (PDF) |

| Isola G200 BT-Epoxy | 3.65 | 0.0150 | 180 | 325 | 55 ppm/°C | G200 Data Sheet |

Low-Loss Materials (High-Speed Digital)

These materials target 10-56 Gbps applications where standard FR-4 causes unacceptable signal loss.

| Material | Dk @ 10 GHz | Df @ 10 GHz | Tg °C | Target Application | Data Sheet |

|---|---|---|---|---|---|

| Isola I-Tera MT40 | 3.38-3.75 (options) | 0.0028-0.0035 | 215 | High-speed backplanes | I-Tera MT40 (PDF) / Dk/Df Tables |

| Panasonic Megtron 6 | 3.37-3.61 (varies by glass) | 0.004 | 185-210 | 25-56 Gbps digital | R-5775 (PDF) / Low-Dk Glass (PDF) |

| Panasonic Megtron 7 | 3.6 @ 1 GHz | 0.0015 @ 1 GHz | 200 | 56-112 Gbps, HDI | R-5785 (PDF) / 50 GHz Data (PDF) |

| Doosan DS-7409DV | 3.62 | 0.0035 | High | Halogen-free high-speed | DS-7409 (PDF) |

| TUC ThunderClad 2 | Low-loss | Low-loss | High | High-speed digital | TU-883 (PDF) |

| TUC ThunderClad 3+ | Ultra-low | Ultra-low | High | 56G+ applications | TU-933 (PDF) |

Note on Megtron 6: Dk varies significantly with glass style - 1035 glass (65% resin) gives Dk 3.37, while 2116 glass (54% resin) gives Dk 3.61. Specify construction when quoting.

Ultra-Low-Loss Materials (112G+ PAM4)

For AI servers, 800 GbE switches, and next-generation data centre applications.

| Material | Dk @ 10 GHz | Df @ 10 GHz | Tg °C | Notes | Data Sheet |

|---|---|---|---|---|---|

| Panasonic Megtron 8 (R-5795) | 3.1 | 0.0012 | 220 | 30% lower loss than Megtron 7 | R-5795 (PDF) / Press Release |

| Isola TerraGreen 400G | 3.05-3.15 | 0.0018 | N/A | Halogen-free | Product Page |

| Isola TerraGreen 400GE | 3.15 | 0.0018 | N/A | Halogen-free | TerraGreen 400GE (PDF) |

| Isola Tachyon 100G | 3.02 | 0.0021 | 220 (DMA) | Established 100G+ material | Tachyon 100G (PDF) |

| ITEQ IT-988GSE | 3.28 @ 28 GHz | 0.0016 @ 28 GHz | >230 | Halogen-free, low-Dk glass | IT-988GSE (PDF) |

| ITEQ IT-988G | 3.3 | 0.002 | >200 | High-speed digital | IT-988G (PDF) |

RF and Microwave Materials

Rogers Thermoset (RO4000 Series)

These hydrocarbon-ceramic materials process like FR-4 but offer RF performance. Note: RO4000 materials are thermoset and do not have a traditional Tg.

| Material | Dk @ 10 GHz | Df @ 10 GHz | CTE (X;Y;Z) | Best For | Data Sheet |

|---|---|---|---|---|---|

| Rogers RO4003C | 3.38 (process) / 3.55 (design) | 0.0027 | 11;14;46 | Lowest loss, general RF | RO4003C/RO4350B (PDF) / Product Page |

| Rogers RO4350B | 3.48 (process) / 3.66 (design) | 0.0037 | 14;16;32 | UL 94 V-0 needed | RO4003C/RO4350B (PDF) / Product Page |

| Rogers RO4835 | 3.48 | 0.0031 | Similar | High oxidation resistance | RO4000 Series |

| Rogers RO4450F Bondply | 3.23 | 0.004 | 16;19;80 | Bonding RO4000 cores | RO4400 Bondply (PDF) |

Fabrication Resource: RO4000 Series Processing Guide (PDF)

PTFE and Ceramic-Filled Materials

| Material | Dk | Df | Test Freq | Notes | Data Sheet |

|---|---|---|---|---|---|

| Rogers RO3003 | 3.00 | 0.0010 | 10 GHz | Industry standard for 77 GHz radar | RO3000 Series (PDF) |

| Rogers RO3003G2 | 3.07 (design) | Low | 10 GHz | Optimised for ADAS | RO3003G2 (PDF) / Product Page |

| Rogers RO3000 Bondply | Varies | Varies | 10 GHz | Bonding RO3000 cores | RO3000 Bondply (PDF) |

| Taconic RF-35 | 3.50 | 0.0018 | 1.9 GHz | PTFE-based, now AGC Multi Material | RF-35 (PDF) |

| Taconic RF-35TC | 3.50 | 0.0018 | 1.9 GHz | Thermally conductive variant | RF-35TC (PDF) |

| Rogers DiClad 522/527/870/880 | 2.5-2.65 | 0.0018-0.0022 | 10 GHz | PTFE/glass, various Dk options | DiClad Series (PDF) / Product Page |

| Rogers RT/duroid 5870/5880 | 2.2-2.33 | 0.0009-0.0012 | 10 GHz | Lowest Dk PTFE | RT/duroid 5870/5880 (PDF) / Product Page |

| Rogers RT/duroid 6006/6010 | 6.15-10.2 | 0.0019-0.0023 | 10 GHz | High-Dk for miniaturisation | RT/duroid 6006/6010 (PDF) |

77 GHz Automotive Radar Materials

The automotive radar market has driven significant material innovation. These materials target 76-81 GHz ADAS applications.

| Material | Manufacturer | Dk @ 77 GHz | Insertion Loss | Data Sheet |

|---|---|---|---|---|

| RO3003 | Rogers | 3.00 | ~1.3 dB/inch | RO3000 Series (PDF) |

| RO3003G2 | Rogers | 3.07 (design) | Low | RO3003G2 (PDF) |

| RO4830 Plus | Rogers | 3.03 | 1.5 dB/inch | Rogers Downloads |

| mmWave77 | Shengyi | 3.06 (design) | 1.29 dB/inch | mmWave77 (PDF) / Alternate (PDF) |

| Astra MT77 | Isola | 3.0 | Low | Astra MT77 (PDF) / Dk/Df Tables |

| PegaClad | TUC | Low-Dk | Low | Product Page |

Design Resource: Rogers Autonomous Driving Design eBook (PDF)

Polyimide and High-Temperature Materials

| Material | Dk @ 1 GHz | Df @ 1 GHz | Tg °C | Application | Data Sheet |

|---|---|---|---|---|---|

| Arlon 85NT | 3.7 | 0.015 | 280 | Flex, high-temp | Arlon 85NT |

| Arlon 55NT | 3.9 | 0.018 | 259 | Thermount reinforced | Arlon 55NT |

Note: Arlon EMD (PCB laminates) is now owned by Elite Material Co. (Taiwan) as of January 2021. Products continue manufacturing in Rancho Cucamonga, CA.

Thermal Management Substrates

| Material | Dk | Thermal Conductivity | Application | Data Sheet |

|---|---|---|---|---|

| Bergquist HPL-03015 | 6.6 @ 1 MHz | High | LED lighting, power | HPL-03015 |

| ITEQ IT-170GRA1 | N/A | ≥3.0 W/m·K | Halogen-free thermal | IT-170GRA1 (PDF) |

Note: Bergquist is now LOCTITE Bergquist (Henkel). Focus is thermal interface materials rather than conventional PCB laminates.

Material Manufacturers

Major Global Suppliers

| Manufacturer | Specialty | Resources |

|---|---|---|

| Rogers Corporation | High-frequency PTFE, thermoset, radar materials | Website / Downloads / Laminate Comparison Tool |

| Isola Group | FR-4, low-loss, ultra-low-loss laminates | Website / Product Guide (PDF) |

| Panasonic | Megtron series low-loss materials | Website |

| AGC Multi Material | Taconic PTFE, Nelco products | Website / About |

| DuPont | Pyralux flex materials | Website |

Asian Suppliers (Now Competitive in Premium Segments)

| Manufacturer | Specialty | Resources |

|---|---|---|

| Shengyi (SYTECH) | mmWave77 for 77 GHz radar, world’s #2 CCL manufacturer | Website / Shengyi USA / RF Products |

| ITEQ Corporation | IT-988GSE ultra-low-loss, high-speed digital | Website / Products |

| TUC | PegaClad for Sub-6G and 77 GHz, ThunderClad | Website |

| Elite Material (EMC) | High-speed laminates, owns Arlon EMD | Website |

| Doosan Electro-Materials | DS-7409 series, PTFE mmWave materials | Website |

| Nan Ya Plastics | Vertically integrated, world’s #4 CCL maker | Website |

Supplier Status Notes

- Park Electrochemical exited the PCB materials business in July 2018. Now Park Aerospace (aerospace composites only).

- Taconic and Nelco are now both part of AGC Multi Material. Product names are retained.

- Arlon was split: EMD division (PCB laminates) sold to Elite Material (Taiwan); silicone products remain with Rogers.

- Bergquist acquired by Henkel in 2014, now LOCTITE Bergquist (thermal TIMs only).

- Laird Performance Materials acquired by DuPont, now branded as Qnity.

Material Databases

These third-party resources aggregate datasheets from multiple manufacturers:

| Resource | Description |

|---|---|

| CircuitData Material Database | Open-source database with 700+ materials |

| everythingRF Laminates | RF-focused material database |

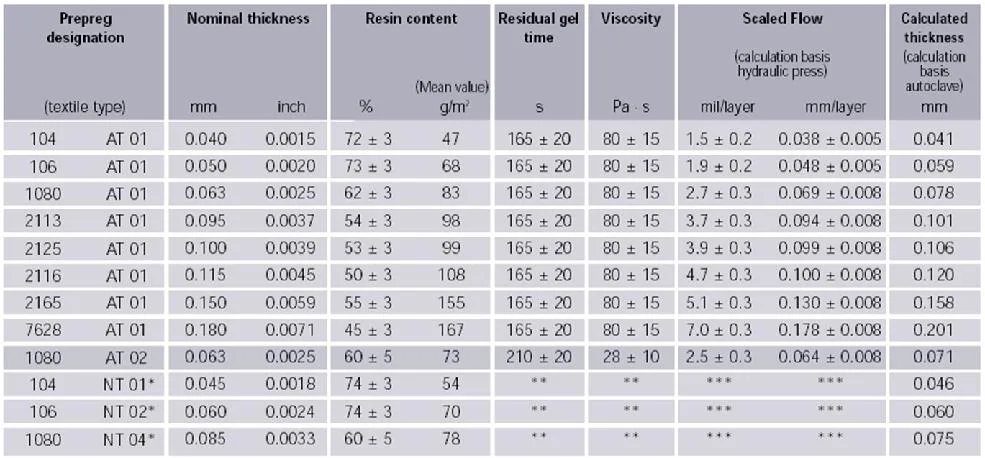

Prepreg Specifications

Standard prepreg specifications for common glass styles

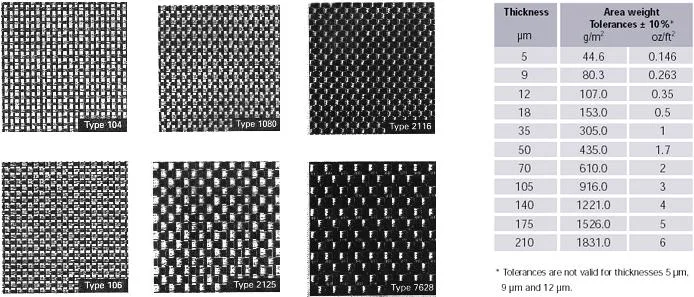

Glass Weaves and Copper Thicknesses

Glass fibre weave types (left) and standard copper thicknesses (right)

Spread Glass Technology

For data rates above 10 Gbps, glass weave effects become significant. Spread glass technology flattens fibre bundles, creating more uniform resin distribution and reducing the Dk difference between glass-rich and resin-rich regions. This reduces glass-weave skew that causes timing problems in high-speed differential pairs.

Isola I-Tera MT40 is available exclusively with spread glass constructions.

Microwave Material Selection

For detailed RF/microwave substrate selection guidance, see our RF and Microwave PCB Substrate Selection Guide - covering frequency thresholds, PTFE processing requirements, hybrid stackup strategies, and application-specific recommendations.

When to Choose Each Material Class

Standard FR-4 (Tg 135-150):

- Digital designs below 1 GHz

- Cost-sensitive applications

- Standard lead-free assembly

High-Tg FR-4 (Tg 170+):

- Multiple reflow cycles

- Automotive and industrial (operating temps to 125°C)

- Improved via reliability for thick boards (>2 mm)

Low-Loss (Megtron 6, I-Tera MT40):

- 10-56 Gbps digital signalling

- Backplanes and high-layer-count designs

- Cost-performance balance

Ultra-Low-Loss (Megtron 7/8, Tachyon, TerraGreen):

- 112 Gbps+ PAM4 signalling

- AI servers and 800 GbE switches

- Where Df ≤0.002 is required

Rogers/Taconic PTFE:

- RF and microwave above 6 GHz

- Low-loss transmission lines

- Tight Dk tolerance requirements

Rogers RO4000 Series:

- RF applications requiring FR-4-like processing

- Mixed RF/digital boards

- When PTFE processing is impractical

Polyimide:

- Flex and rigid-flex designs

- High-temperature environments (>150°C continuous)

- Aerospace and defence

Frequently Asked Questions

What Dk value should I use for impedance calculations?

Use the Dk value measured at the frequency closest to your operating frequency. FR-4’s Dk varies from ~4.5 at 1 MHz to ~4.2 at 10 GHz. For RF designs, use materials with Dk specified at 10 GHz. Rogers provides both “process” Dk (for manufacturing) and “design” Dk (for simulation) - use the design value for impedance calculations.

When do I need high-Tg FR-4?

High-Tg materials (170°C+) are required for lead-free assembly with multiple reflow cycles, thick boards (over 2 mm) where via stress is higher, and automotive applications with operating temperatures up to 125°C per AEC-Q standards.

What happened to Arlon? Is it still separate from Rogers?

Arlon was split. Rogers acquired Arlon LLC in January 2015 and retained the silicone products. The PCB laminate division (Arlon EMD) was sold separately and is now owned by Elite Material Co. (EMC) of Taiwan as of January 2021. Arlon EMD continues manufacturing polyimide and high-Tg materials in Rancho Cucamonga, CA.

Are Nelco and Taconic materials still available?

Yes. AGC Inc. (Japan) acquired Park Electrochemical’s Nelco brand in December 2018 and Taconic in June 2019. Both product lines continue under AGC Multi Material with original product names retained.

Is Megtron 6 obsolete now that Megtron 7 and 8 exist?

No. Megtron 6 remains widely used and is not superseded. It offers excellent performance (Df ~0.004 @ 10 GHz) at lower cost than Megtron 7/8 and is appropriate for many high-speed applications below 112 Gbps.

What are the best materials for 77 GHz automotive radar?

Leading materials include Rogers RO3003/RO3003G2 (industry standard), the new Rogers RO4830 Plus (2025, thermoset option), Shengyi mmWave77 (cost-competitive alternative), and Isola Astra MT77 (FR-4 process compatible).

Which Asian suppliers match Rogers/Isola for premium applications?

Shengyi (mmWave77), ITEQ (IT-988GSE), Doosan (DS-7409 series), and TUC (PegaClad) now offer materials genuinely competitive with Western suppliers for high-frequency and high-speed digital applications. About 70% of high-speed CCL production is now based in Asia.

What Df is required for 112 Gbps PAM4 signalling?

Target Df ≤0.002 @ 10 GHz. Suitable materials include Megtron 8 (Df 0.0012), TerraGreen 400G (Df 0.0018), and Tachyon 100G (Df 0.0021).

What’s the difference between Tg and Td?

Tg (glass transition) is where the material softens but remains structurally intact - the board can still function. Td (decomposition) is where chemical breakdown begins. Your operating and processing temperatures must stay well below both. Note that Rogers RO4000 series materials are thermoset and do not have a traditional Tg.

What are the halogen-free requirements?

Per IEC 61249-2-21: Chlorine ≤900 ppm, Bromine ≤900 ppm, Total Cl+Br ≤1500 ppm. While not mandatory everywhere, halogen-free materials are increasingly specified. Options include Isola TerraGreen series, ITEQ IT-988GSE, and Doosan DS-7409DV.

Related Articles

- RF and Microwave PCB Substrate Selection - Detailed RF material guidance with frequency thresholds

- Controlled Impedance PCB Design - How dielectric constant affects impedance

- RoHS Effect on PCBs - Tg requirements for lead-free assembly

- Multilayer PCB Capabilities - Material options in our capability table

Need help selecting materials? Request a quote - we’ll recommend the best laminate for your electrical and thermal requirements.